EasyMount Ussing Chamber - Model P2300

The P2300 EasyMount Ussing Chamber is designed as a versatile and reliable instrument for experimental research focused on transport and barrier functions of biological tissues and cell monolayers. It incorporates an intuitive design that accommodates a broad range of sample types, from native animal tissues to cultured cell layers on permeable supports, with straightforward integration into both standard and customized laboratory workflows. Equipped with precision-engineered EasyMount Ussing Chamber slider inserts, the P2300 simplifies the setup and alignment of samples, minimizing handling time and enhancing reproducibility, crucial for consistent results across ussing chamber experiments.

The ussing chamber’s flexibility in half-chamber volume (2.0–7.0 ml) allows researchers to tailor the setup to specific experimental needs, optimizing resources while maintaining accuracy. With durable construction materials suited for frequent use and compatibility with various physiological measurement devices, our ussing chamber - model P2300 is not only adaptable but also built to last, supporting the rigorous demands of high-quality research in physiology, pharmacology, and related fields.

⦿ To be used with P2300 EasyMount Ussing Chamber Slider Inserts- Regular price

- $703.00

- Regular price

-

- Sale price

- $703.00

- Unit price

- per

EasyMount Chamber Details

EasyMount Ussing Chambers - Model: P2300

The EasyMount Ussing Chamber - model P2300, is designed for researchers conducting advanced studies on animal tissues and cell cultures. This chamber offers a streamlined solution for mounting tissues or permeable membrane supports, supporting a wide range of experimental needs. By enabling seamless compatibility with membrane supports such as Snapwell, Transwell, Millicell, and Nunc, the P2300 Ussing Chamber in conjunction with the P2300 Ussing Chamber Slider inserts offer versatility across various applications in physiological and pharmacological research.

Overview of the EasyMount Ussing Chamber

Engineered with precision, the ussing chamber provides an efficient approach for mounting tissues and permeable membrane supports, making it highly adaptable for diverse experimental needs. Compatible with widely used membrane supports such as Snapwell, Transwell, Millicell, and Nunc, the chamber supports a range of applications, facilitating studies across various scientific fields. This adaptability makes it a valuable tool for researchers seeking consistency across different experimental setups.

Key Features:

-

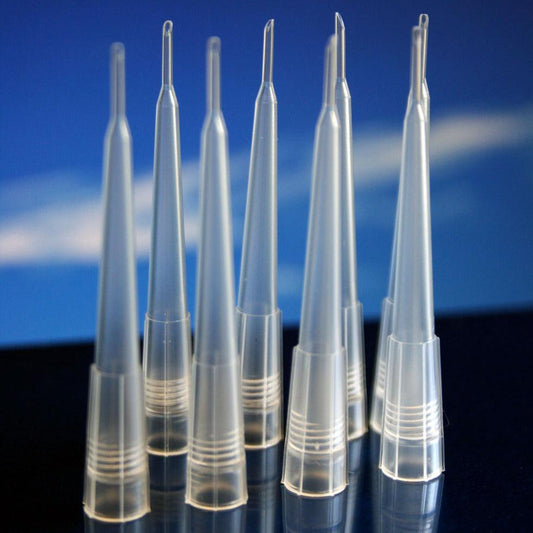

Ussing Chamber Sliders: The custom-designed EasyMount Ussing Chamber Sliders simplify the mounting process, ensuring a secure and precise fit for tissue samples and membrane supports. This design promotes reproducibility, a key factor in reliable scientific data. The EasyMount Ussing Chamber sliders (inserts) enhance both the consistency and accuracy of experimental results, streamlining workflow and reducing setup complexity.

-

Flexible Volume Range: With a usable half-chamber volume range from 2.0 to 7.0 ml, the P2300 provides flexibility for various experimental protocols. This adaptability allows researchers to conduct different types of assays without extensive adjustments, saving time and resources while accommodating a range of study needs.

-

Compatible with Snapwell, Transwell, Millicell, and Nunc Culture Inserts: This chamber offers a streamlined solution for mounting tissues or permeable membrane supports, supporting a wide range of experimental needs. By enabling seamless compatibility with membrane supports such as Snapwell, Transwell, Millicell, and Nunc, the P2300 offers versatility across various applications in physiological and pharmacological research.

With a thoughtful design focused on precision, ease of use, and durability, the EasyMount Ussing Chamber is an invaluable tool for researchers in physiology and pharmacology. Built to support diverse studies and ensure reliable data, the ussing chamber empowers researchers to advance their work with confidence, offering a reliable, efficient, and adaptable system for tissue and cell culture studies. More than just a tool, the ussing chamber is a crucial asset in the pursuit of scientific discovery.